Sheet metal bending machine

A sheet metal bending machine is a type of machine used to bend and shape sheet metal into various forms and shapes. It is commonly used in the manufacturing industry for the production of metal parts and components.

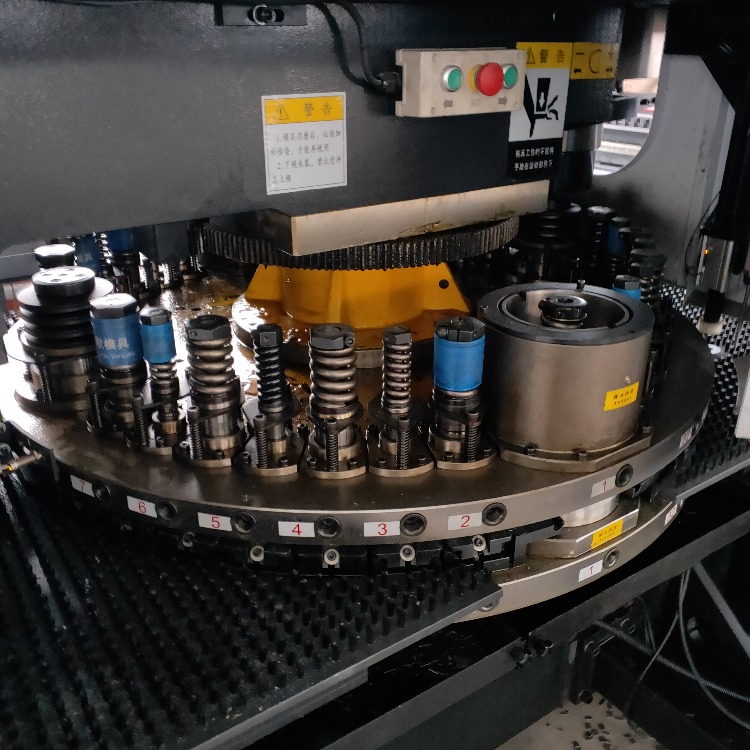

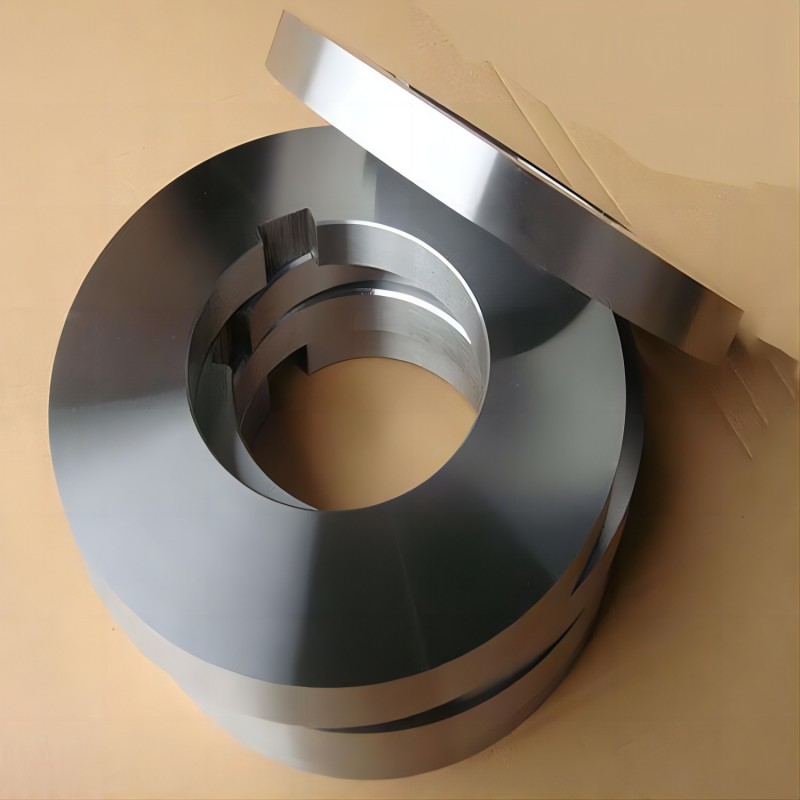

The machine works by clamping the sheet metal between a set of dies and applying pressure to bend the metal into the desired shape. The dies can be adjusted to create different angles and shapes, allowing for a wide range of bending possibilities.

Sheet metal bending machines come in various sizes and types, including manual, hydraulic, and CNC-controlled machines. Manual machines are operated by hand and are suitable for small-scale production. Hydraulic machines use hydraulic pressure to bend the metal and are suitable for medium to large-scale production. CNC-controlled machines are computer-controlled and offer precise and accurate bending capabilities, making them ideal for high-volume production.

Sheet metal bending machines are used in a variety of industries, including automotive, aerospace, construction, and electronics. They are used to produce a wide range of products, including brackets, enclosures, frames, and panels.

When selecting a sheet metal bending machine, it is important to consider factors such as the size and thickness of the metal being bent, the required bending angle and radius, and the production volume. It is also important to ensure that the machine is safe to operate and meets all relevant safety standards.

In conclusion, a sheet metal bending machine is an essential tool for the manufacturing industry, allowing for the production of high-quality metal parts and components. With the right machine and proper training, manufacturers can achieve precise and accurate bending results, leading to increased efficiency and profitability.